how does a brake line compression fitting work

We are only trying to. Air line fitting not tight enough.

Splicing Brake Line Compression Fitting Killing Me Tccoa Forums

15 high-pressure rubber hose.

. EQUIPPED WITH AN ENGLARGED DIE SET COMPRESSION AREA for better grip of dies. 98 of products ordered ship from stock and deliver same or next day. Transmission Parts Mounts.

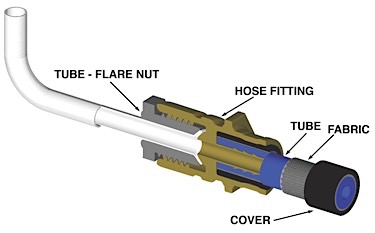

Fitting thread size chart is intended as a quick reference guide for thread size by dash size. The lines screw in but requires extra force due to the improper thread match and leaks occur. A hollow barrel-shaped compression ring sometimes called a ferrule.

If carrying 80 PSI pressure these pipes will carry slightly less. Galv Stainless Grooved Fittings Adapters Clamps. Equus 3612 Compression Tester Kit features a large easy-to-read 2-12 dial face with dual-calibrated colour-coded scales.

Metric bubble flare 475 6 8 and 10mm mini. Flare fittings are metal to metal compression seals deformed with a cone nut and pressed into a flare mating. Clutch Parts.

Unless the water is the problem of pulling out the lead from the solder joints there isnt a problem. I used a 69 vette master I believe its 1 bore. They are typically made of brass or plastic but stainless steel or other materials may be used.

Using the fittings for public transportation vehicles or those that use public highways and roads is against the law in many states and a bad idea. Compression is a critical part of an engines combustion without it or more specifically without the right amount of compression your engine will not produce power efficiently. It is easy to flip the block over and have the clip on the opposite side of the tab.

Mathematically the net amount of useful work that the engine provides is that generated in the power stroke minus that used during the compression. If carrying 120 PSI pressure these sizes will carry slightly more air than shown or pressure loss will be slightly less than 1 PSI. Compression fittings sometimes called lock-bush fittings consist of a tapered concave conical seat.

Push air line into the air fitting so it is secure. A piece of air line which has not been cut off square at the end. One 12 mm and one 14 mm adapter included for broader applications such as motorcycles ATVs snowmobiles and watercraft.

And a compression nut which is threaded onto the body of the fitting and tightened to make a leakproof connection. Where are the oxygen sensors on 2001 Chevy s10 answers com April 15th 2019 -. If your engine is not producing the correct compression this can be due to parts such as the piston rings valves or.

Now its plastic pipe rolled type mostly. Clutches Transmission Parts. Side-release valve allows repeated tests without disconnecting the hose.

If a single brake control is fitted effective braking control must remain on at least one wheel if part of the system fails. Aeroquip Flexmaster Expansion Joints. Looking for Prorack SP167 Replacement Parts.

Front Brakes Suspension. Disc Brake Kits Ball Joint Disc Brake Kits Link Pin Disc Brake Kits Super Beetle Drum Brakes. An engine is a sealed chamber designed to keep compression in.

The Feds started requesting lead tests in the late 80s or very early 90s. To lower the compression you can go with a re-bore and fit lower compression pistons you can add a stroker kit to alter the compression ratio by adjusting the compression stroke length. Air Brake DOT Push-In Fittings For Nylon Tube PushConnect Expansion Joints Flexmaster Jo.

Loose valve core in air. For minor adjustments you could get a larger head and thicker head gasket thus increasing the combustion chamber volume thereby reducing the compression ratio. A motorcycle manufactured after June 1988 and fitted with a sidecar must have an effective park brake applied by mechanical means that can hold the vehicle.

Flaredouble flare 316 14 516 38 and 12. 4 If the installation equipment or power line is operating at 300 volts or over but less than 750 volts a suitably equipped competent person who is able to perform rescue operations including cardio-pulmonary resuscitation shall be readily available and be able to see the worker who is performing the work. Someone did a lot of work to put a compression fitting in a very difficult location.

Face seal metal flanges with a groove and o-ring seal are fastened together. Shop online and get the best price and right advice from Automotive Superstore - 100 Aussie Owned - Free Shipping 99. Been searching the net for an hour trying to find it with no luck.

We offer 316 14 38 and 516 Copper- Nickel Stainless Steel PVF- Coated Steel Brake Line Replacement Brake Line Kits Fuel Line Tubing Transmission Coils and Brake Line Flaring Tools. 8MILELAKE Brake Caliper Wind Back Tool 24pcs Professional Disc Brake Caliper Tool Set. If the vehicle is for off-road usage or undergoing a restoration you can use the fittings for temporary repairs.

Our support team is standing by to ensure all questions are answered. As far as solder inside the home. Brake line fitting sizes Ricks Free Auto Repair Advice The smaller size is 3164.

Brake line compression fittings work well under certain circumstances. Air Brake DOT Compression Fittings For Rubber Hose Misc. I would start at the master and loosen the line fitting put on safety goggles wrap a rag around the fitting and have someone press the brake pedal.

Air line is not completely pushed in. 930 Turbo Drivetrain Conversion. It must also include a warning light to indicate that a failure in the system has occurred.

Includes 19 adapters fitting hundreds of vehicle makes and models including American European and Japanese. So depending on what the. The compression stroke is the first and during this work is done on the gas to compress it and so energy is expanded.

The second phase is the power stroke in which the expanding gases force the piston to move. 24pcs pad and caliper wind back set to replace brake pads and rotate pistons back into the caliper. They are compression fitting.

Keep in mind that while the fittings offer an inexpensive. I called the musclecar place I bought the brake kit from and he said 316 line is used for front discs. GM fuel line flare brake lines and transmission 516 and 38.

McMaster-Carr is the complete source for your plant with over 700000 products. When measuring lengths of runs add 5 of length for each pipe fitting. Then loosen the line at the splitter and repeat fluid check process then check the lines as they leave the splitter.

All of our products stand behind our lifetime warranty. When replacing the brake lines you need to note how the driver-side brake block is installed. Remove air pressure from system and re-cut air line tube and ensure it has a square end.

Why not replace the entire line. If fluid is present and the pedal travels to the floor then the culprit is likely a clogged line. Find answers to car repair questions learn how to troubleshoot problems get free auto repair estimates and research do-it-yourself car maintenance.

O-ring boss the fitting is screwed into a boss and orientated as needed an additional nut tightens the fitting washer and o-ring in place. It was 5050 for a great many years. Then changed to Silver solder.

Power Steering Steel Braided Line Kit 185 Powder coating 700 Wilwood Mustang II ProSpindles 230 5 on 5 or 6 lug bolt pattern 336 Standard 1 Solid Sway Bar 324 Torsion Spline Sway Bar 700 Steel Braided Brake Lines wBanjo fitting for GM Calipers 98 Wilwood 4-Piston Caliper Upgrade 336. Tighten air fitting 14 to 12 more turns. THIS TOOL CAN BE USED ON annealed steel.

Connecting Brake Lines With A Compression Fitting Youtube

Top 3 Reasons Not To Use Brake Line Compression Fittings Brakeconnect

How To Connect Brake Lines With New Fittings A Union Youtube

Will A Compression Fitting Work On Brake Lines Youtube

Top 3 Reasons Not To Use Brake Line Compression Fittings Brakeconnect

Tom S Vw Pages Steel Brake Line Repairs

Brake Line Repair Tubing Fittings

Brake Line Repair When To Use A Compression Fitting Doityourself Com